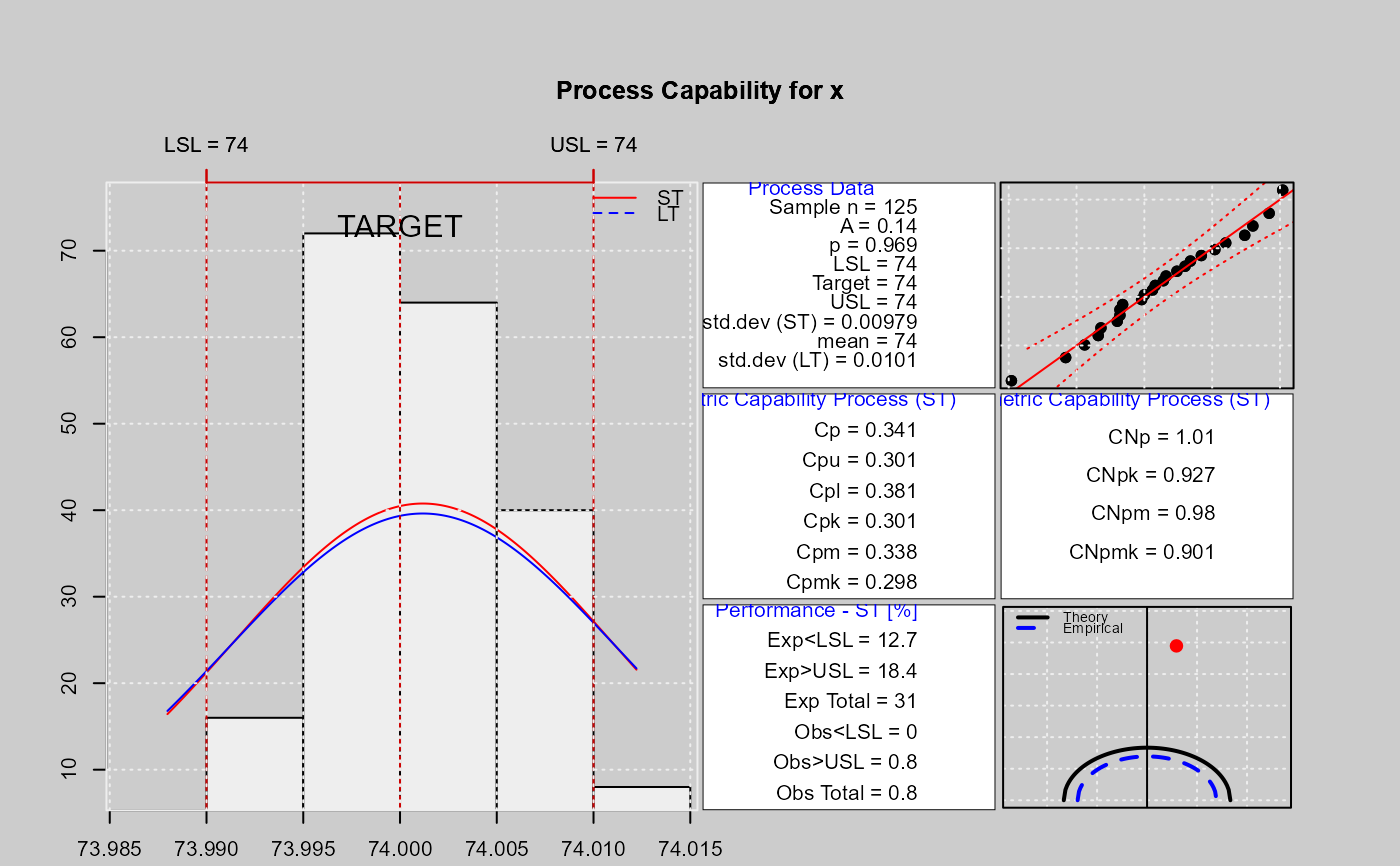

Calculates the process capability indices Cp, Cpk, Cpl, Cpu, Cpm, Cpmk for a qcs object and normal distribution. Also, this function calculates confidence limits for \(C_p\) using the method described by Chou et al. (1990). Approximate confidence limits for \(C_{pl}\), \(C_{pu}\) and \(C_{pk}\) are computed using the method in Bissell (1990). Confidence limits for \(C_{pm}\) are based on the method of Boyles (1991); this method is approximate and it assumes the target is midway between the specification limits. Moreover, calculates the process capability indices CNp, CNpk, CNpm, CNpmk for a qcs object. A histogram with a density curve is displayed along with the specification limits, a Quantile-Quantile Plot for the specified distribution and contour graph is plotted for estimate the index Cpm.

Usage

qcs.ca(

object,

limits = c(lsl = -3, usl = 3),

target = NULL,

std.dev = NULL,

nsigmas = 3,

confidence = 0.9973,

plot = TRUE,

main = NULL,

...

)Arguments

- object

qcs object of type

"qcs.xbar"or"qcs.one".- limits

A vector specifying the lower and upper specification limits.

- target

A value specifying the target of the process. If it is

NULL, the target is set at the middle value between specification limits.- std.dev

A value specifying the within-group standard deviation.

- nsigmas

A numeric value specifying the number of sigmas to use.

- confidence

A numeric value between 0 and 1 specifying the probabilities for computing the quantiles. This values is used only when

objectvalues is provided. By defaultconfidence=0.9973.- plot

Logical value indicating whether graph should be plotted.

- main

Title of the plot.

- ...

Arguments to be passed to or from methods.

References

Montgomery, D.C. (1991) Introduction to Statistical Quality Control, 2nd

ed, New York, John Wiley & Sons.

Tong, L.I. and Chen, J.P. (1998), Lower con???dence limits of process capability

indices for nonnormal process distributions. International Journal of Quality & Reliability Management,

Vol. 15 No. 8/9, pp. 907-19.

Vannman, K (1995) A Unified Approach to Capability Indices. Statitica Sinica,5,805-820.

Vannman, K. (2001). A Graphical Method to Control Process Capability. Frontiers in Statistical Quality Control,

No 6, Editors: H-J Lenz and P-TH Wilrich. Physica-Verlag, Heidelberg, 290-311.

Hubele and Vannman (2004). The E???ect of Pooled and Un-pooled Variance Estimators on Cpm When Using Subsamples.

Journal Quality Technology, 36, 207-222.

Examples

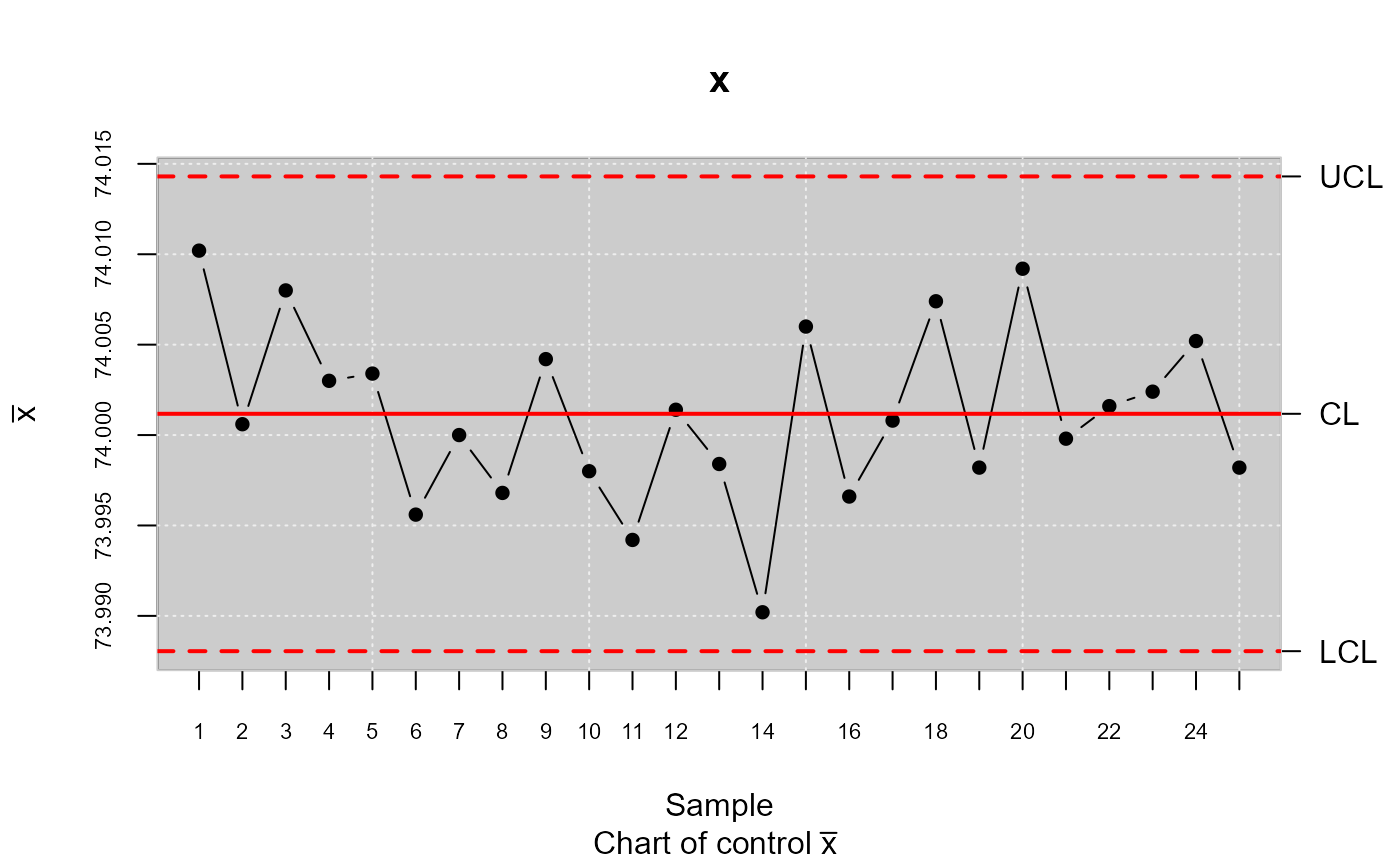

library(qcr)

data(pistonrings)

xbar <- qcs.xbar(pistonrings[1:125,],plot = TRUE)

LSL=73.99; USL=74.01

limits = c(lsl = 73.99, usl = 74.01)

qcs.ca(xbar, limits = limits)

#>

#> Process Capability Analysis

#>

#> Call:

#> qcs.ca(object = xbar, limits = limits)

#>

#> Number of obs = 125 Target = 74

#> Center = 74 LSL = 73.99

#> StdDev = 0.009785 USL = 74.01

#>

#> Paremetric Capability indices:

#>

#> Value 0.1% 99.9%

#> Cp 0.3407 0.2771 0.4065

#> Cp_l 0.3807 0.2739 0.4875

#> Cp_u 0.3006 0.2021 0.3991

#> Cp_k 0.3006 0.1944 0.4068

#> Cpm 0.3382 0.2749 0.4038

#>

#>

#> Non parametric Capability indices:

#>

#> Value

#> CNp 1.0082

#> CNpK 0.9275

#> CNpm 0.9799

#> CNpmk 0.9015

#>

#>

#> PPM:

#>

#> Exp<LSL 1.267e+07 Obs<LSL 0

#> Exp>USL 1.836e+07 Obs>USL 8e+05

#> Exp Total 3.103e+07 Obs Total 8e+05

#>

#> Test:

#>

#>

#> Anderson Darling Test for normal distribution

#>

#> data: xbar

#> Error in round(x$statistic, 4): non-numeric argument to mathematical function

LSL=73.99; USL=74.01

limits = c(lsl = 73.99, usl = 74.01)

qcs.ca(xbar, limits = limits)

#>

#> Process Capability Analysis

#>

#> Call:

#> qcs.ca(object = xbar, limits = limits)

#>

#> Number of obs = 125 Target = 74

#> Center = 74 LSL = 73.99

#> StdDev = 0.009785 USL = 74.01

#>

#> Paremetric Capability indices:

#>

#> Value 0.1% 99.9%

#> Cp 0.3407 0.2771 0.4065

#> Cp_l 0.3807 0.2739 0.4875

#> Cp_u 0.3006 0.2021 0.3991

#> Cp_k 0.3006 0.1944 0.4068

#> Cpm 0.3382 0.2749 0.4038

#>

#>

#> Non parametric Capability indices:

#>

#> Value

#> CNp 1.0082

#> CNpK 0.9275

#> CNpm 0.9799

#> CNpmk 0.9015

#>

#>

#> PPM:

#>

#> Exp<LSL 1.267e+07 Obs<LSL 0

#> Exp>USL 1.836e+07 Obs>USL 8e+05

#> Exp Total 3.103e+07 Obs Total 8e+05

#>

#> Test:

#>

#>

#> Anderson Darling Test for normal distribution

#>

#> data: xbar

#> Error in round(x$statistic, 4): non-numeric argument to mathematical function